Plant effectiveness modelling

Research purpose

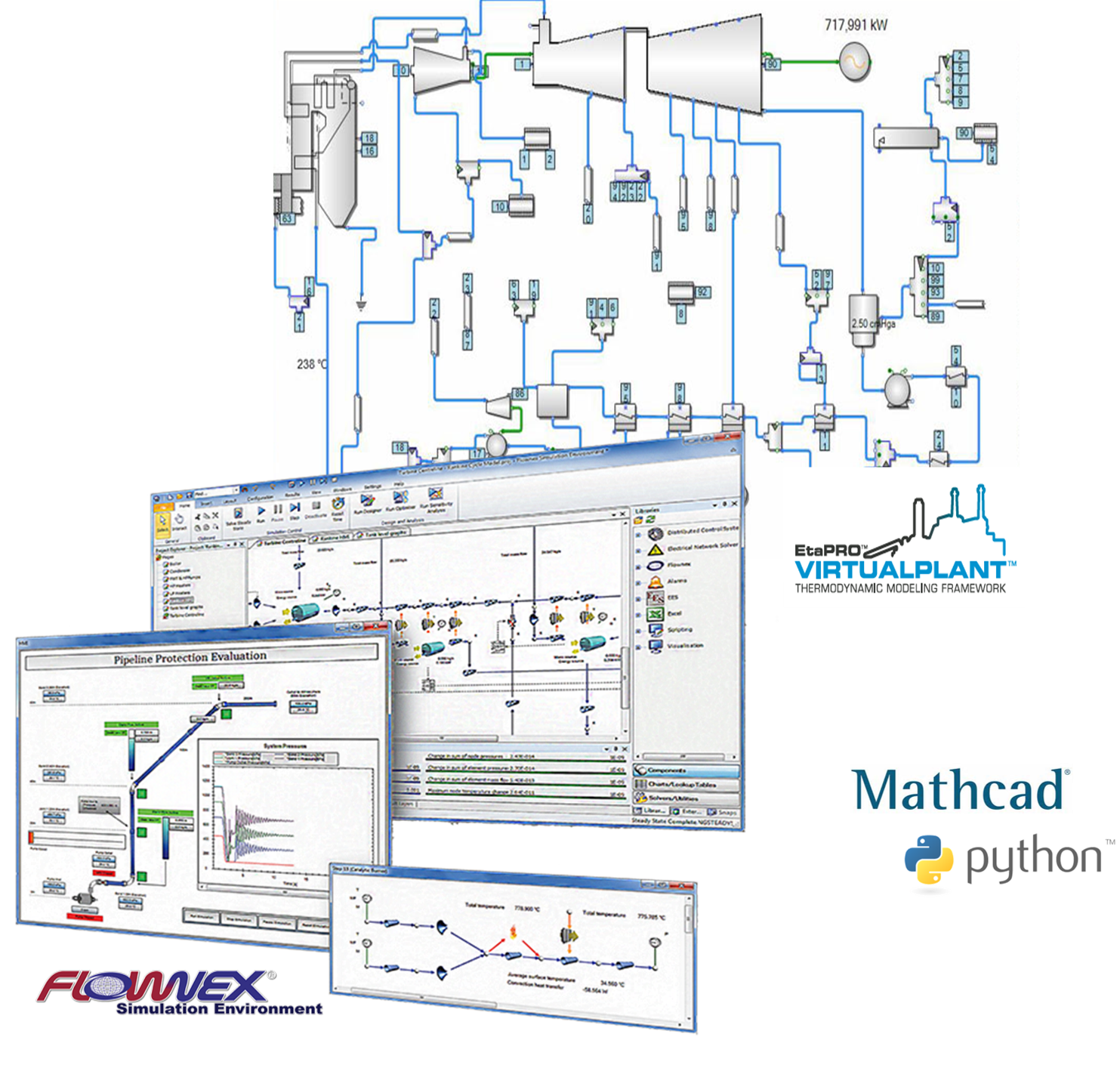

To develop a high-fidelity power plant engineering simulator that can serve as a platform for various other process related studies.

Research vision

It is envisaged that the models built for the simulator will allow the Group to perform integrated plant operation studies. The simulator will also be applicable in other research areas.

The simulator will have the following characteristics:

- Built on the Flownex Simulation Environment, extended by custom-developed coding where necessary.

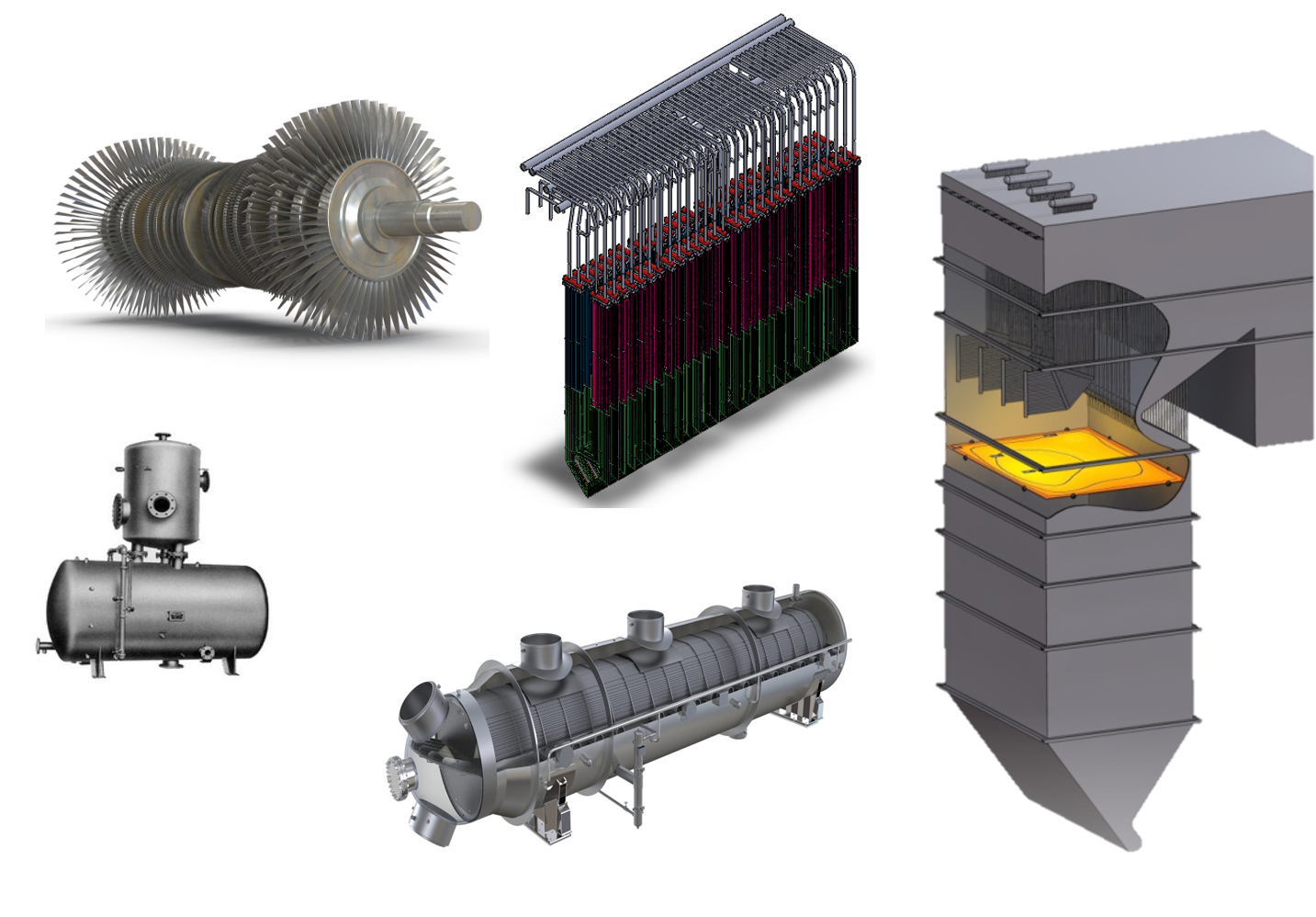

- Consist of properly researched and validated power plant components.

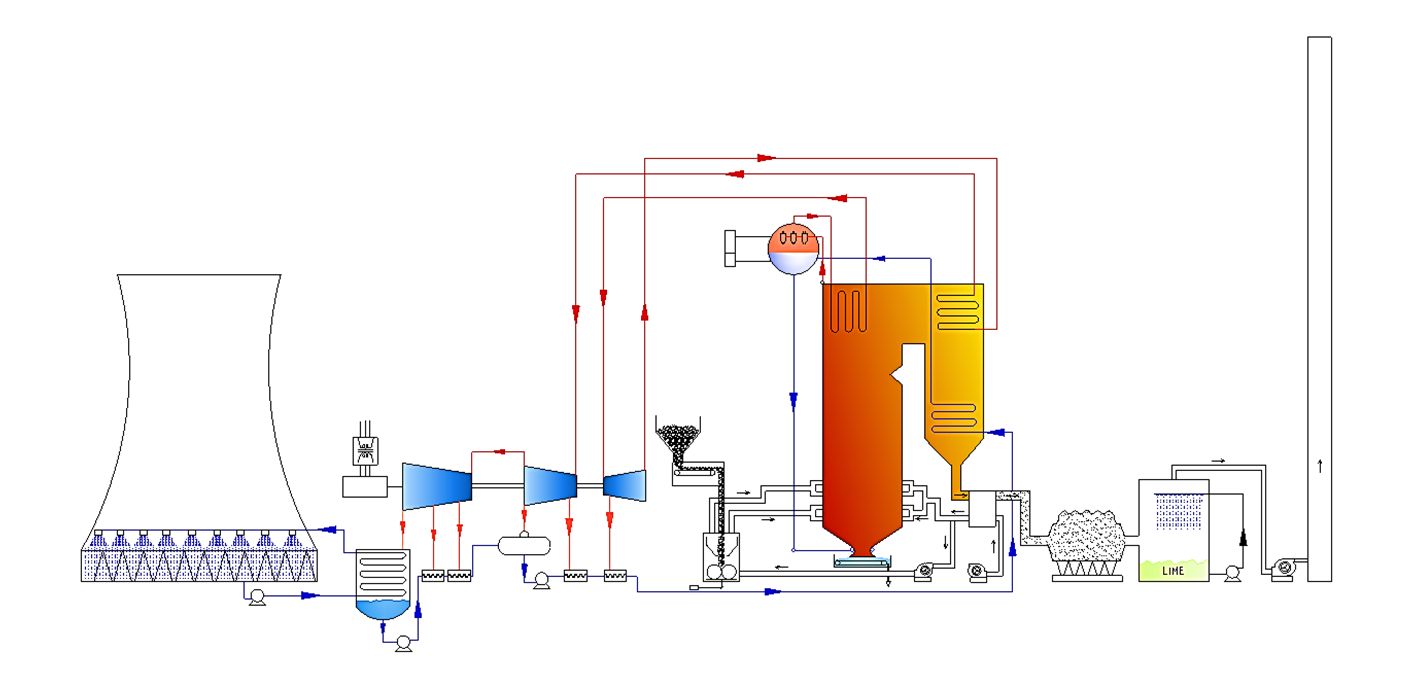

- Consist of all major flow streams, i.e. coal, air/flue gas and steam/water.

- Be able to capture the transient processes of a plant, i.e. contain the correct thermal inertia and physics representing time-based process changes.

- Contain a highly flexible control architecture to enable various operational studies.

Transient and low load operation

Research purpose

To develop network-based process models which can be applied in studying the effects of low load as well as varying load operation in coal fired power plants.

Research vision

Research in this area will contribute towards overcoming three challenges experienced on coal fired power plants due to the increase of renewable electricity generating technologies on the supply grid:

- Stable minimum generation operation when demand is reduced in order to minimize shut-down and start-up cycles and the associated lifetime consumption of thermally stressed components.

- Flexibility to meet changing demands by allowing higher load following gradients both positive and negative.

- Identify operating principles that could lead to improved asset life, reduce risks of unit trips and improve plant availability as well as overall fleet efficiency.

Power Plant Condition Monitoring

Research purpose

The ultimate purpose of the Power Plant Condition Monitoring (PPCM) research is to improve plant availability, reliability, efficiency and safety and thereby to reduce the overall cost of generation. As a first step, the purpose is to advance on-line process condition monitoring associated with the major systems, sub-systems and components of coal-fired power plants, through research as well as through engineering studies in the form of post-graduate projects. The major systems involved are the PF supply system, air supply system, steam generator or boiler system, flue gas cleaning system, turbine system, cooling system and generator system.

Research vision

For efficient condition monitoring methodologies to be implemented, accurate numerical process models of the systems and components are required in their ideal operating states. Condition monitoring systems typically compare the results of models with the actual operating behaviour/performance to identify deviations from the intended behaviour/performance. Such comparison is usually done with the models running on-line in parallel with the real plant. When behaviour/performance parameters between the ideal and real plant deviate beyond defined acceptable thresholds, engineers need to be alerted by the condition monitoring system to take appropriate action.

In this research, the aim will be to develop and/or verify on-line condition monitoring algorithms that are diagnostic and predictive in nature and biased towards improving availability rather than thermal performance only. The research/engineering approach will combine real-life measurements, appropriate data analysis techniques, fundamental thermofluid process modelling, data synthesis and display with appropriate alarms. Furthermore, rather than just focussing on solving specific problems at specific power stations, these process models and methodologies will be used as a vehicle to integrate knowledge and experienced gained at all the different stations and to make it available on a fleet-wide basis.

Therefore, the specific research and development objectives of the PPCM program are to:

- Identify and specify key on-line measurements required on power plants to support and enhance process condition monitoring.

- Develop and validate advanced component and process models and modelling methodologies.

- Develop and apply innovative data analysis and statistical techniques and identify key plant and component performance metrics.

- Develop innovative on-line process condition monitoring algorithms that are predictive in nature and biased towards improving availability in order to support outage scoping and life cycle management decisions.

- Support implementation of outputs from the research to contribute to the improvement of availability, reliability, efficiency and safety of components and systems, as well as to improve the training of engineers and technicians.