Our research activities are defined by a commitment to advancing Materials Science and Engineering in South Africa.

Our work spans various materials, focusing on exploring the relationships between process, structure, property, and performance. This approach enables us to address fundamental and applied research challenges, emphasising support for South Africa's manufacturing industry.

A key aspect of our research is directed towards developing a competitive and sustainable manufacturing industry in South Africa. We recognise that the industry's growth is contingent upon developing and nurturing expertise in Materials Engineering. To this end, our research activities are integrated into a multidisciplinary framework that seeks to strengthen manufacturing technologies. This integration allows us to develop the necessary human resources to support a burgeoning manufacturing economy in South Africa.

Our research activities also aim to develop expert knowledge of how materials perform during service, assessing their remnant life and implementing remedial actions when necessary. Our work focus includes high-temperature strength and creep performance, fatigue and fracture behaviour, and corrosion and chemical degradation of materials. These efforts are particularly relevant to the chemical, energy, mining, construction, and marine industries in South Africa.

We are committed to developing materials and processes that enhance performance and contribute to a sustainable future. Our research integrates sustainable practices by focusing on materials that can be produced, used, and disposed of to minimise environmental impact. By prioritising sustainability, we aim to support South Africa's manufacturing industry in becoming more environmentally responsible, ensuring that the advancements will continue to benefit society and the planet in the long term.

Our research activities are inherently interdisciplinary, involving collaborations with academic institutions, industry partners, and government agencies. These partnerships enable us to tackle complex materials-related challenges and ensure that our research aligns with national priorities. Our commitment to high-impact research is reflected in our focus on producing publishable outputs in leading international journals and conferences, thereby contributing to the global body of knowledge in the field.

CME research infrastructure provides the facilities and equipment necessary to support experimental work. This includes advanced mechanical testing laboratories, microstructure characterisation facilities, and specialised processing equipment. Our research projects are closely tied to postgraduate education, actively involving students in research that advances their technical skills. We also emphasise inclusivity, attracting and developing postgraduate students and postdoctoral fellows from diverse backgrounds, ensuring that our research community reflects the rich diversity of South African and African society.

Research Groups

The Centre is structured around specialised research groups, each dedicated to advancing knowledge and innovation within specific areas aligned with our strategic goals. These groups have been established to concentrate their expertise and resources on critical research challenges. By maintaining a focused research agenda, each group contributes to the broader goals of the Centre. These groups, their focus areas, and active projects are summarised alphabetically below. Listed projects might be singular PhD studies or span across several MSc projects.

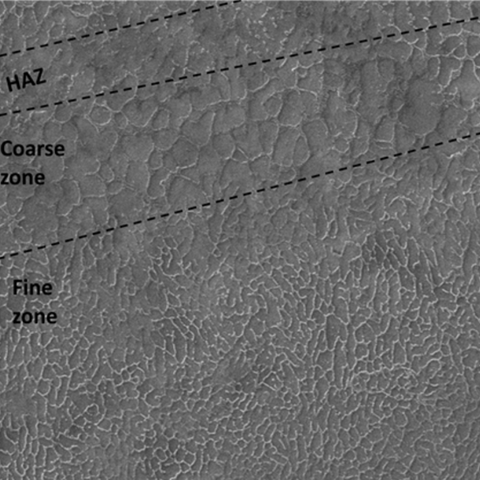

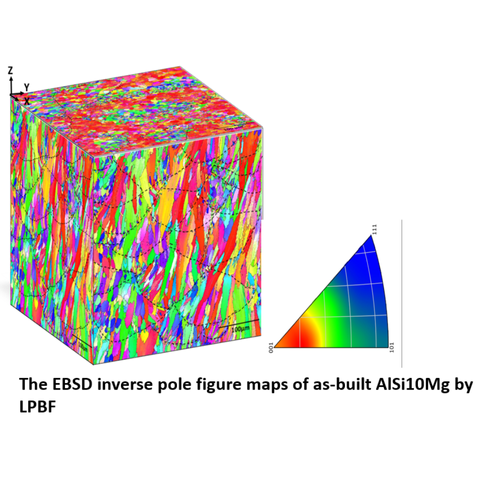

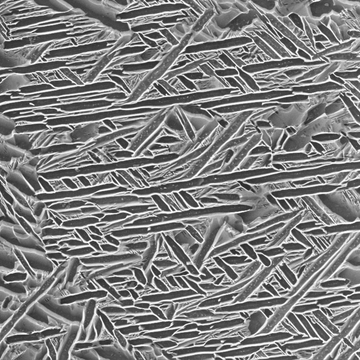

Under the South African Collaborative Programme in Additive Manufacturing (CPAM), the research group focuses on advancing the commercialisation of Additive Manufacturing processes. The overarching aim is to establish a robust and reliable Additive Manufacturing (AM) process that consistently produces high-quality, load-bearing, and capable fabricated parts. This initiative aligns with South Africa’s AM Strategy, which aims to position South Africa as a key player in the global AM market. The strategy focuses on establishing the properties of materials produced using AM as well as developing new materials, enhancing process capabilities, and ensuring product quality.

One of the significant challenges in the widespread adoption of AM is the variability in the mechanical properties of produced parts. Several factors, including the characteristics of the alloy, the feedstock powder, the specific AM process parameters, and the subsequent post-processing treatments, influence this variability. The group aims to address these challenges through a multi-faceted approach that includes characterising and qualifying titanium-based alloys, nickel-based superalloys, precipitation hardenable aluminium alloys and shape memory alloys, as well as developing new beta-titanium alloys, and refining post-processing techniques such as heat treatments and surface finishing techniques.

The group’s work is highly collaborative, involving partnerships with various academic institutions and industry stakeholders, both locally and internationally. For instance, the collaboration with KU Leuven leverages their expertise in microstructural development. The partnership with ETH Zurich focuses on advancing AM technologies using multi-materials, and the collaboration with Nanyang Technological University focuses on fatigue and fracture of AM alloys.

Team

| Team Member | Focus Area |

|---|---|

| Prof Thorsten Becker (Principal Investigator) | Structural integrity, fatigue and fracture, Additive Manufacturing, digital image and volume correlation, computational mechanics |

| Dr Nasheeta Hanief | Scanning and transmission electron microscopy |

| A/Prof Debby Blaine (Stellenbosch University) | Powder metallurgy, physical metallurgy |

| Prof Natasha Sacks (Stellenbosch University) | Advanced manufacturing, metal matrix composites, tribology, Additive Manufacturing |

| Dr Melody Neaves (Stellenbosch University) | Additive Manufacturing, creep, high-temperature testing, digital image correlation |

| Mr Maxwell Vos | Gleeble engineer |

Funding / Partners

CME has had a long-standing research relationship with various aluminium industry role players, with Hulamin Rolled Product being the most prominent. Through this collaborative relationship, a focus on aluminium metallurgy has been established, and the context of aluminium metallurgy has become a golden thread through the post-graduate knowledge-building pathway in the CME, most notably through the presentation of the Wrought Aluminium Course. The increased research focus on aluminium has been the catalyst for the growth of Aluminium research, where CME has established itself as the leading research team in South Africa in the field of wrought aluminium products and processes. The group is also endorsed by the Aluminium Federation of South Africa (AFSA) and was represented on the steering committee to finalise the South African Aluminium Industry Masterplan document for the DSI.

The ARG strives to make a difference in South Africa's aluminium industry. Its research focus is driven by industrial and applied research and centres around various facets of aluminium processing and its value chain. The areas of expertise encompass a range of critical research areas, such as experimental physical metallurgy, computational and modelling techniques, and machine learning and data science applications. The research that the ARG is currently working on is being fed back into the industry and is starting to have a meaningful impact on the collaborating industry partners.

Team

| Team Member | Focus Area |

|---|---|

| Mr Ernesto Ismail (Principle Investigator) | Design, computation/modelling, machine learning |

| Dr Sarah George | Physical metallurgy and thermomechanical processing |

| Dr Gerard Leteba | Advanced transmission electron microscopy characterisation techniques |

| Mr James Hepworth | Instrumentation and sensors |

Funding / Partners

CME has a history of expertise in the field of fracture mechanics, originally established by Emeritus Professor Robert Tait as one of the leading organisations in this discipline within South Africa. While Fracture Mechanics is a broad field, CME focuses on advancing the measurement of failure and fracture properties in laboratory-based settings, using modern measurement techniques such as Digital Image Correlation (DIC), Digital Volume Correlation (DVC), and High-angular Resolution Electron Backscatter Diffraction (HR-EBSD) to enhance the accuracy and reliability of these measurements.

The research is centred on advancing the understanding of failure and fracture properties by developing and applying DIC and DVC techniques. These methods provide a unique advantage over traditional approaches, offering detailed failure property information across a wide range of materials, resulting in a more precise understanding of their fracture behaviour. The group aims to comprehensively understand the material property and failure mechanisms by combining full-field displacement or strain data with computational models. This integration allows for considering various factors, such as material heterogeneities, complex loading conditions, and different crack propagation modes. These are crucial for developing predictive models applicable to engineering design and analysis of materials and structures.

Team

| Team Member | Focus Area |

|---|---|

| Prof Thorsten Becker (Principal Investigator) | Structural integrity, fatigue and fracture, Additive Manufacturing, digital image and volume correlation, computational mechanics |

| Dr Devan Atkinson | Digital Image and Volume Correlation, machine learning |

| Dr Abdo Koko (National Physical Laboratory, United Kingdom) | Micromechanics, strain measurements, materials characterisation, fatigue and fracture |

Funding / Partners

A new focus has been directed toward the green hydrogen economy in developing advanced materials for green hydrogen applications, explicitly targeting the challenges associated with hydrogen embrittlement in conventional materials. The work aims to design, synthesise, and characterise existing and new alloy systems that demonstrate resistance to hydrogen-induced damage. It integrates fundamental materials science with applied engineering, investigating the atomic-scale interactions between hydrogen and alloy systems alongside computational tools such as CALPHAD and advanced experimental techniques, including neutron diffraction and electron microscopy.

The work is motivated by global sustainability goals, particularly the crucial role of green hydrogen in achieving carbon neutrality. The group aims to contribute to practical solutions for the hydrogen economy by advancing the understanding and development of hydrogen embrittlement alloys.

Team

| Team Member | Focus Area |

|---|---|

| Prof Thorsten Becker (Principal Investigator) | Structural integrity, fatigue and fracture, Additive Manufacturing, digital image and volume correlation, computational mechanics |

Funding / Partners

The Sustainable Composites Group focuses on characterising sustainable materials under extreme loading conditions and investigating blast wave propagation in urban environments. The research aims to develop and optimise materials that can withstand high strain and impact forces, including blast loads while serving as sustainable alternatives to conventional petroleum-based materials. Emphasising both sustainability and practical implementation within South Africa, the group's work contributes to creating safer, more environmentally conscious engineering solutions that are also cost-effective and feasible for local industries. Additionally, the group explores the complex dynamics of blast waves in urban settings, conducting small-scale tests with modelled buildings to understand the impact of explosive loads better and enhance safety measures. By integrating these research areas, the group aspires to develop resilient structures capable of enduring extreme conditions while minimising their environmental footprint.

Team

| Team Member | Focus Area |

|---|---|

| Dr Sherlyn Gabriel (Principal Investigator) | Composites manufacturing, composite constituent materials, blast and impact loading, urban blast environments |

| Mr James Dicks | Polymer matrices, polymer synthesis |

Funding / Partners

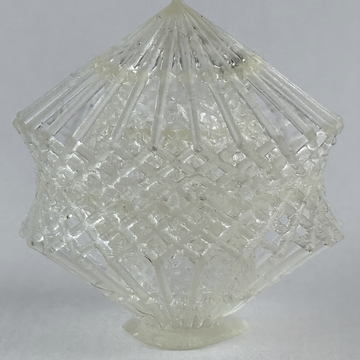

The Sustainable & Specialty Polymer Group evolved from research on biobased polymers and composites that began under Chris Woolard in 2017. Officially established in 2022 and now led by James Dicks, the group aims to address a future-centred approach to polymers through the development of sustainable polymers and polymers for advanced engineering applications. Research areas within the group include the valorisation of agri-resources from industrial crops and agricultural waste streams for the efficient synthesis of monomers aligned to the principles of “green chemistry”, the synthesis of monomers for polymers with specialised properties such as covalent adaptable networks, chemically recyclable polymers, self-healing polymers, and shape memory polymers, the application of novel monomers for additive manufacturing technologies to produce innovative 3D printed polymers, and the optimisation of additive manufacturing technologies to enhance the performance of the 3D printed polymers.

Team

| Team Member | Focus Area |

|---|---|

| Mr James Dicks (Principal Investigator) | Monomer and polymer chemistry, materials characterisation, mechanical properties, Additive Manufacturing |

| A/Prof Wei Hua Ho | Computational fluid dynamics, ocular fluid dynamics, biofluids |

Funding / Partners