About the BScHons(Materials Science) degree programme

The BScHons(Materials Science) degree programme is an exciting one-year intensive programme offered by the Department of Mechanical Engineering in the Faculty of Engineering and the Built Environment at the University of Cape Town. The programme is structured with both coursework and a laboratory-based research project, providing candidates with both theoretical and practical skills and knowledge within the field of Materials Science. The programme focuses on multiple facets of Materials Science, providing a well-rounded foundation for multiples classes of materials, in depth understanding of the underlying principles of materials, and associated analytical techniques. The degree programme is grounded within the Centre for Materials Engineering, which gives BScHons candidates valuable exposure and participation with research activities within the Centre, form part of the vibrant postgraduate and staff community, and provides opportunities for research participation related to numerous industry collaborations and associations that are ongoing within the Centre research activities.

Programme curriculum

The BScHons(Materials Science) degree programme is structured with seven courses (totalling 84 credits) and a research project (36 credits). The programme provides the BScHons(Materials Science) candidate with both theoretical and practical skills and knowledge in the field of Materials Science.

Course code: MEC4137Z

NQF Credits: 12

NQF level: 8

Course convener: Prof R Knutsen

Course outline:

This course provides an introduction to the crystallography of metallic materials (description and representation), the influence of thermodynamics and kinetics on alloy phase constitution and microstructure development, solidification and solid-state phase transformations, and metal deformation and annealing phenomena.

Course code: MEC4133Z

NQF Credits: 12

NQF level: 8

Course convener: Prof T Becker

Course outline:

This course provides an understanding of the relationship between the design, environmental conditions and material properties on the reliable and safe operation of engineering structures. This understanding is presented through the link between the process, structure, and material properties, with discussions on the deformation behaviour and failure mechanisms. Topics include elastic and plastic deformation, plastic slip, strengthening mechanisms, stress concentrations and fracture mechanisms, linear elastic fracture mechanics approach, crack initiation and propagation, and creep. Furthermore, the course aims to provide real-world failure case studies to emphasise the topics

discussed and the performance of the material.

Course code: MEC4134Z

NQF Credits: 12

NQF level: 8

Course convener: Mr J Dicks

Course outline:

This course presents a range of experimental techniques commonly employed in the characterisation of engineering materials. The principles, apparatus setup, operation and measurement parameters, measurement optimisation for data acquisition, and measurement analysis are explored to provide a sound understanding of materials characterisation. Topics include: sample preparation for materialography, optical microscopy apparatus and techniques, electron microscopy apparatus and techniques (SEM, TEM, EDS, and EBSD), materialography image analysis, thermodilatometry, differential scanning calorimetry, thermogravimetry, and X-ray diffraction. Throughout the course,

various case studies are presented to illustrate both the potential and limitations of each technique, where complementary techniques can be employed, and the use of each technique to draw structure-property relationships.

Course code: MEC4135Z

NQF Credits: 12

NQF level: 8

Course convener: Prof T Becker

Course outline:

This course provides a detailed insight into the experimental techniques for determining the mechanical properties of engineering materials. The course provides an overview of commonly used mechanical testing techniques, sample preparation, metrology, measurement analysis, and statistical methods. Commonly employed testing techniques are covered, including: hardness; quasistatic (tensile, compression, and bending), impact, fracture toughness, fatigue, fatigue crack growth rate, creep, and a selection of specialised techniques. An emphasis is placed towards practical aspects of the mechanical testing procedures and techniques, and optimisation of the information acquired from the experimental results obtained.

Course code: MEC4136Z

NQF Credits: 12

NQF level: 8

Course convener: Mr J Dicks

Course outline:

This course offers an insight into a selection of functional and contemporary engineering materials. The course investigates the societal contributions and development of materials within a selection of fields, and develops an understanding of sustainable materials. Throughout the course, case studies

are used to demonstrate the relationships between structure-properties-processing-performance of materials in contextually driven applications.

Course code: MEC4100Z

NQF Credits: 12

NQF level: 8

Course convener: Mr J Dicks

Course outline:

This course aims to develop an advanced understanding of the structure, processing, and properties of polymeric materials. Topics include: polymer nomenclature; morphology; bonding; molecular weight, polymerization, crystallisation; polymer types; rheology; applications; polymer identification; polymer modification, additives; analytical techniques; biodegradability; and

selection and design. Throughout the course the relationships of structure-properties-processing are described.

Course code: END5044Z

NQF Credits: 12

NQF level: 8

Course convener: Mrs A Gwynne-Evans

Course outline:

This course aims to develop students’ skills and understanding of the importance of effective communication within the professional environment. It provides the opportunity to consolidate practical experience and knowledge of a variety of communication formats including reports, business proposals and online platforms, applying these to the context of academic writing, including referencing. Students learn the requirements for written and oral communication in terms of planning, organisation and selection of information, as well as in terms of linguistic and oral style and final presentation. Students will have to demonstrate proficiency in both written and oral formats.

Course code: MEC4091Z

NQF Credits: 36

NQF level: 8

Course convener: Dr S George

Course outline:

Students are required to attend a series of lectures and practicals on experimental techniques. Each student will be given an individual laboratory project on a problem relating to materials. A period of twelve weeks is allocated for the project and on completion a treatise must be submitted for examination.

Application process for BSc(Hons) Materials Science

Application for the programme is conveniently performed online via the UCT PeopleSoft process. In order to apply online you will need a working email address and your South African identity number, or, if you are an international applicant, your passport number. Click here to apply online* If you do not have internet access the application process is described here: Click here The degree code for BSc(Hons) in Materials Science is EH005MEC04

Acceptance to the programme is limited and eligibility is based on academic merit. Preference is given to candidates who complete their first degree in the relevant minimum period and who obtain at least 65% in one major subject in the final year.

Should you wish to enquire further about the degree programme or need assistance with the application process, please feel free to contact the programme convener, James Dicks (james.dicks@uct.ac.za), or the postgraduate administrator Denise Botha (denise.botha@uct.ac.za)

*Please note that during the PeopleSoft application you may choose to apply for one additional degree programme of second preference at UCT.

Want to find out more about Materials Science?

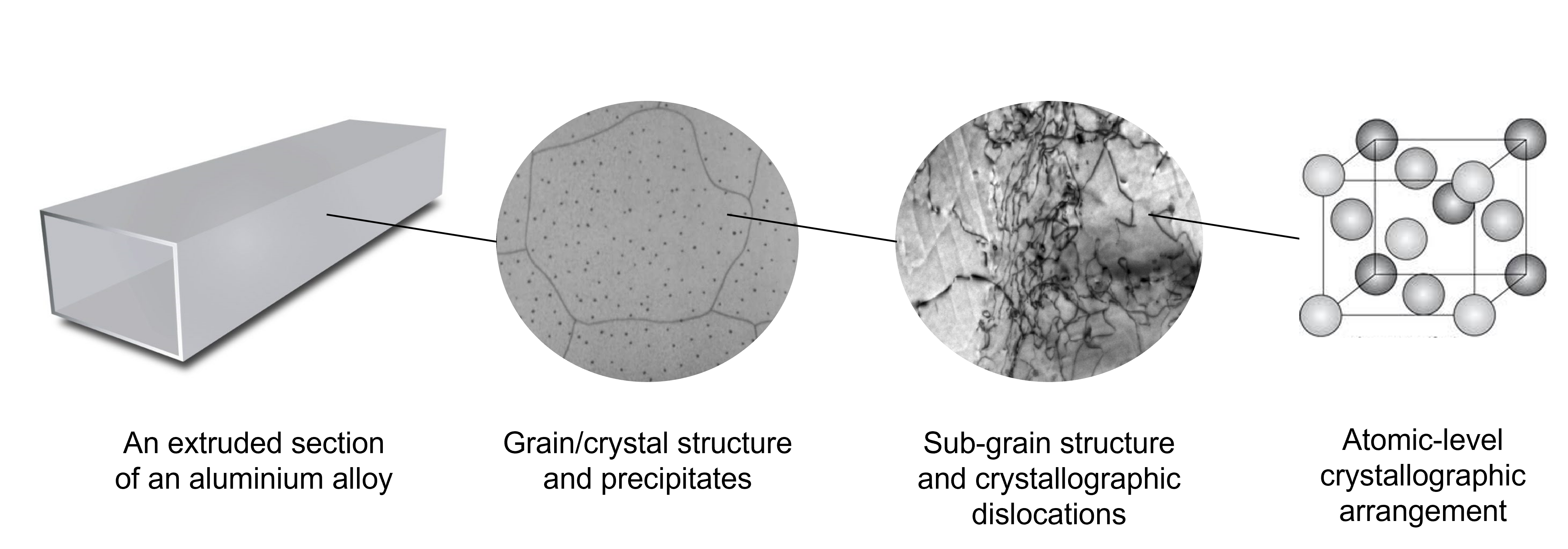

A material is any substance that an object is made from. What differentiates one material from another depends on the atomic structure, type of bonding between atoms, and the arrangement of atoms present in that substance. Looking around your daily life, you can probably identify that there are thousands of different materials used for different applications. In your day-to-day life, you could also probably identify that some materials are naturally occurring, such as wood from trees, whilst others are human made, such as ‘plastics’.

There are several classification systems we can use to group different types of materials together. One of the most common classifications is based on the type of bonding present in the material. Using this system, we can group materials as either metals, polymers, or ceramics. Additionally, composites are considered another class of material, where two or more different materials are combined to make a total material with properties different to either of its substituents.

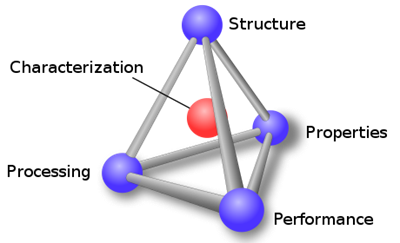

Different materials each have their own set of properties. A material’s properties include their chemical, physical, optical, electrical, thermal, and mechanical properties. The properties of a material are determined by its structure how it was processed, which in turn will influence the material’s performance in a given application.

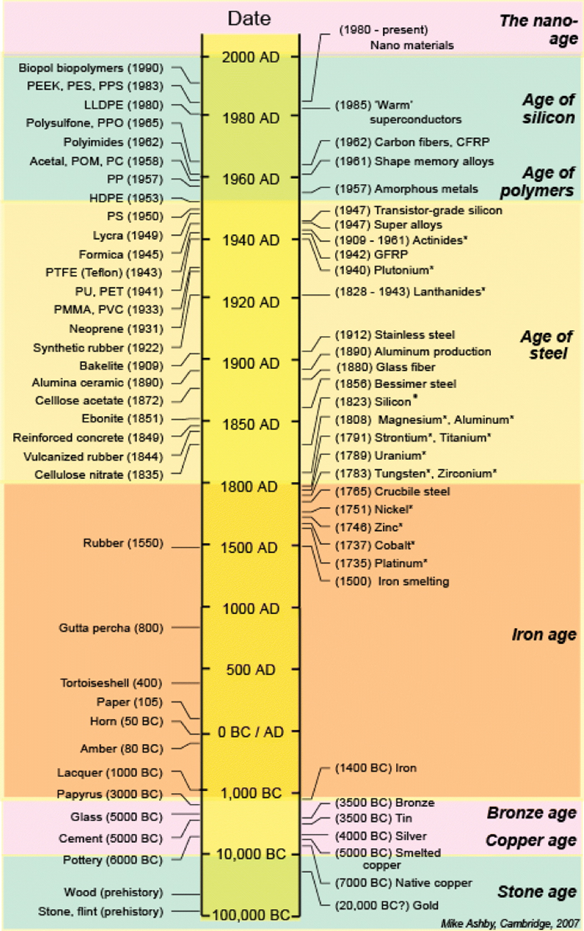

The relationship between humans and materials goes back over 100 000 years into prehistory. Humans’ use of materials is as old as humans have been in existence. Indeed, materials have been so important to our development that many human-related time frames are described by the materials we were using in that era, such as the Stone Age or the Iron Age. Materials have contributed significantly towards the operation of our contemporary society and the way we live; from buildings to electronic devices, it is in part the understanding, designing, and development of suitable materials for an application that has allowed these advances to be realised. As such, materials have a role in the future that we build for ourselves and the environment alike; including our ability to harness and store energy, transportation, infrastructure, medical progress, electronic and technological advancement, commodities, and even our leisure and expression in the creative arts.

In order for a material to be considered “useful”, it needs to perform well for its application. These criteria are generally described by the material’s properties. When we talk about a material’s properties, we are talking about how the material responds to its environment. We can also find that phenomenological changes in structure in different environments lead to differences in properties. These properties include its strength, hardness, and stiffness when a force is applied to the material, brittleness or ductility, how it behaves at a certain temperature, its density, alongside numerous other properties.

A materials scientist primarily investigates the relationships between the structure, properties, processing, and performance of materials. The understanding of these relationships allows a materials scientist to predict or manipulate a material’s structure and properties to be suitable or optimised for a given application. Furthermore, a materials scientist may develop a new material, and its properties need to be analysed to assess its viability for an application. The term “characterisation” is often used to describe the techniques a materials scientist uses to establish these relationships.

In order to establish the relationships between structure, properties, processing, and performance, in other words to “characterise” a material, a material scientist needs to measure and analyse information about the material. These measurements can either be empirical (actual measurements) or simulated (computational).

Common empirical techniques include:

- Mechanical testing (tensile, flexural, compression, hardness, fatigue, and other complex configurations)

- Thermal testing (thermogravimetry, differential scanning calorimetry, dynamic mechanical analysis, thermodilatometry)

- Microscopy (optical, scanning electron, transmission electron, electron backscatter diffraction)

- Single crystal and powder x-ray diffraction

- Elemental analysis (x-ray fluorescence, electron dispersive spectroscopy, optical/atomic absorption/emission spectroscopy)

- Spectroscopic structural analysis (Fourier transform infrared spectroscopy, Raman spectroscopy, nuclear magnetic resonance spectroscopy, mass spectroscopy)

- Corrosion analysis

- Furthermore, it is common to prepare samples and manipulate their structures through processes such as rolling metals into thin sheets, exposure to salt water and corrosive environments, heat treatments in a furnace, rapid cooling (quenching),

Common computational methods include:

- Finite element analysis

- Density functional theory

Materials science encompasses a broad range of skills and is often considered an interdisciplinary subject with a variety of different fields of study. Historically, materials science is considered a combination of physics, metallurgy, chemistry, and engineering. Therefore, students with several undergraduate BSc degrees are suitable to specialise in materials science.

BSc graduates with at least one of the following majors are considered:

- Chemistry

- Physics

- Geology

- Biochemistry