Background

The central focus of process mineralogy research is the application of mineralogical knowledge for the understanding, optimisation, modelling and prediction of the unit processes of comminution, classification and flotation. Process mineralogy forms a key linkage in the research activities of these different unit operations. Research is broadly divided into two themes: mineral-texture and mineralogical alteration processes, the former predominantly manifesting as variations in recovery, and the latter as variations in grade. Since both themes share the same fundamental mineralogical and ore forming processes, the research findings are applicable to a variety of different ore types (including PGM and base metals). Both research themes are relevant in the broader discipline of geometallurgy. The research is underpinned by the acquisition of mineralogical information, and the development of methodologies, descriptors and approaches of representing this information in appropriate and usable formats.

Research Themes

Mineral texture: Research focuses on understanding the effects of different mineral textures on comminution, classification and flotation and linking this knowledge to the original ore forming and subsequent alteration processes. This research includes the development of methods and descriptors for mineral textural characterisation of particulates (e.g. liberation and association, grain size distribution) and drill core samples, in two and three dimensions. Ultimately this information finds application in mineralogical modelling. Some good progress with mineralogical modelling has been made in partnership with the Minerals to Metals Initiative.

Mineral alteration processes: Research focuses on understanding the effects of different mineral alteration reactions (oxidation, supergene enrichment, and hydrolysis) on comminution, classification and flotation. Understanding the effects of the alteration reactions on the valuable minerals is more ore specific (and focused here on PGM and copper ores), compared to the effects of the alteration reactions on the gangue minerals (the majority of which are common in all ores). The specific focus on gangue minerals centres on phyllosilicate alteration minerals such as talc, chlorite, serpentine, and clays which are increasingly more prevalent in the ores currently processed in the mining industry.

Activities Supporting Research Themes

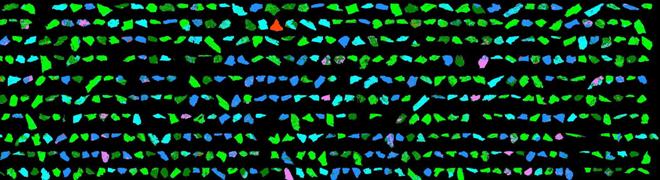

Mineralogical characterisation: The ‘work-horse’ for mineralogical characterisation is the CMR QEMSCAN instrument (Quantitative Evaluation of Mineralogy by Scanning Electron Microscopy). The instrument is used for the characterisation of drill core, comminution product, flotation feed, concentrates and tailings in terms of their bulk mineralogy, element deportment, mineral liberation and association, grain size distribution in two dimensions, across a range of commodities. X-ray computed tomography scanning (XCT) is used as a complimentary tool for mineralogical characterisation in three dimensions where the focus lies in being able to represent the internal structure of drill core or particulate samples.

Phyllosilicate mineral characterisation: A fundamental mineralogical characteristic of the phyllosilicate minerals is their anisotropic surface charge and therefore research in this area focuses on quantifying the manifestation of these effects on non-Newtonian slurry rheology, naturally floating gangue and froth properties. Many of these effects are exacerbated by fine grinding which is increasingly practised in the industry.