QEMSCAN (Quantitative Evaluation of Minerals by Scanning Electron Microscopy) is the state of the art, top of the range automated mineral analyser. It is an analytical tool which provides rapid, reproducible and statistically reliable quantitative information on minerals and certain man-made materials for a variety of disciplines. This tool has been custom developed for the mining industry.

Our QEMSCAN 650F (pictured here) uses a field emission gun-scanning electron microscope (FEG-SEM) from FEI combined with high resolution BSE (Back scattered electron), state-of-the-art Bruker energy Dispersive Spectrometers (EDS) and a Spectral Analysis Engine (SAE) to analyze phases.

Analysed phases are classified as specific minerals according to their BSE and chemical composition compared to that within a user developed, reference mineral library known as a SIP file (Species Identification Protocol). During QEMSCAN analysis, a detailed database of statistically representative mineral particle information is built up, which is later interrogated by the user.

QEMSCAN measurement types

- Bulk Mineralogical Analysis (BMA) – rapid line scan analysis to obtain good statistics on bulk mineralogy

- Particle Mineralogical Analysis (PMA) – detailed particle mineralogical information

- Specific Mineral Search (SMS) – detailed particle mineralogical information on only specific minerals of interest (e.g. sulfides)

- Trace Mineral Search (TMS) – detailed particle mineralogical information on trace mineral phases (e.g. Au, PGM)

- Field scan – detailed mapping of larger samples (e.g. drill core, crushed particles)

Information obtained from QEMSCAN

- Bulk mineralogy of samples

- Element deportment

- Ore characterization

- Estimated grain and particle size

- Particle images

- Grain and particle shape

- Mineral liberation

- Mineral association

- Theoretical grade recovery curve

Sample Preparation

- Representative samples are obtained by splitting and riffling

- Sized samples are mixed with graphite, mounted in resin and allowed to cure (30 mm round moulds)

- Sample blocks are carefully polished to a 1µm diamond finish

- Carbon coating

Mpho Ramanugu (NRF Intern) and Lorraine Nkemba (Sample preparation) carbon coating QEMSCAN blocks in preparation for analysis.

The CMR QEMSCAN forms an integral part of many research projects, both within the CMR and other groupings at the University of Cape Town. The QEMSCAN is housed in the New Engineering Building. For more information, please contact Dr Megan Becker.

This equipment was financially supported by the Department of Science and Technology in partnership with the National Research Foundation, South Africa, 2014.

View QEMSCAN poster.

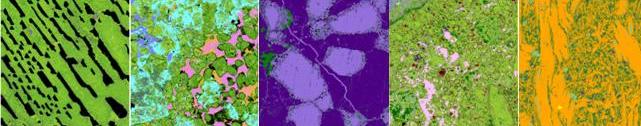

QEMSCAN field images of various South African rocks: Each tile represents a 1 x 1cm false colour image.

CMR QEMSCAN Team: Dr Megan Becker (QEMSCAN manager), Gaynor Yorath (Instrument operator), Lorraine Nkemba (Sample preparation), Mpho Ramanugu (NRF Intern).