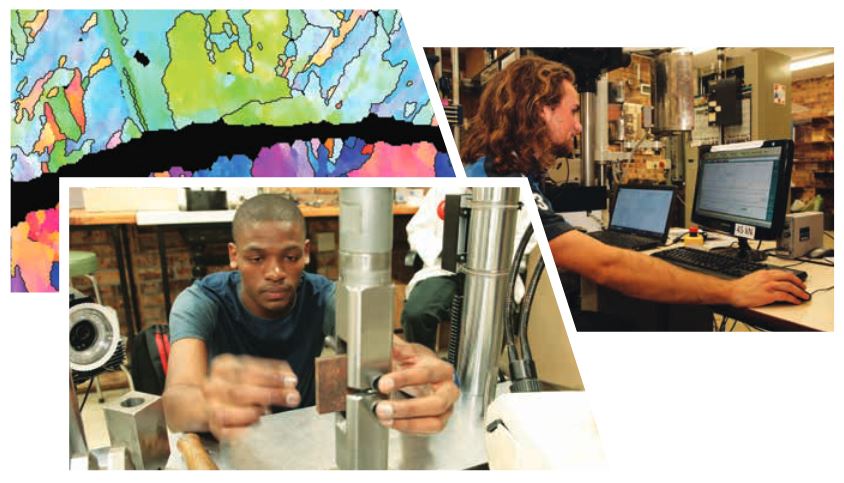

The equipment base in the Centre for Materials Engineering has been developed over a number of years to underpin the research carried out. Since we are concerned with the physical, chemical, electrical and mechanical properties of ceramic, polymeric, metallic and composite materials, the equipment ranges from microscopes to investigate the fine microstructure to large mechanical testing equipment. The Centre for Materials Engineering is very well equipped with materials testing facilities, both of a commercial nature and custom-built for specific simulation testing. Since many items of equipment exist in the Centre, it is convenient to divide them into the following equipment suites:

- Metallographic Preparation.

- Microscopy (including several light microscopes and access to the electron microscope suite in the UCT EM Unit).

- Heat Treatment furnaces.

- Thermal Analysis including dilatometry, scanning calorimetry and thermogravimetric analysis.

- Mechanical Testing including a range in screw-driven and hydraulic universal testing machines (loadcell capacity from 5kN to 250kN).

- Hardness Testing (2g – 150kg load) and high/low energy impact testing.

- Corrosion Testing.

- Creep testing