Our state-of-the-art laboratories make use of the latest industry standards to support modern, world-class teaching and learning and cutting-edge research.

Electronics workshop

The Electronics Workshop serves the numerous research groups within the Department and develops custom electronics hardware, software and test rigs. It is housed in room 3.13 of the Chemical Engineering Building. View the Electronics Workshop Webpage for more information.

Analytical Laboratory

The Analytical Laboratory has a dedicated 4-member Team to provide analytical and material characterization services to the Department of Chemical Engineering, other departments at UCT, as well as other Universities and small-medium companies. The laboratory is equipped with an AAS, ICP-OES, MP-AES, LECO-sulphur analyser for elemental analysis, and a microwave digester to assist in the acid digestion of samples. The laboratory also houses a Mastersizer and Zetasizer for particle size analysis, and a rheometer for rheology experiments. Other equipment includes a TriStar for surface area and pore size/volume measurements, ASAPs for chemisorption, AutoChems for temperature-programmed studies.

Visit their website here.

Departmental Facilities

These are facilities and analysis options which can be catered for within the Chemical Engineering Department.

Liquid and gas chromatography is performed using various detection methods such as UV/VIS or RID for liquid chromatography, FID, TCD or MS-detection for gas chromatography. Furthermore, two dimensional GC analysis is performed using GCxGC with TOF-MS.

In addition, the department has some unique equipment in the form of an in-situ magnetometer (for measurement of content of magnetic material present under high temperature and high pressure conditions) and a novel in-situ XRD set-up (for monitoring in-situ transformations within solid materials at elevated temperatures and pressures)

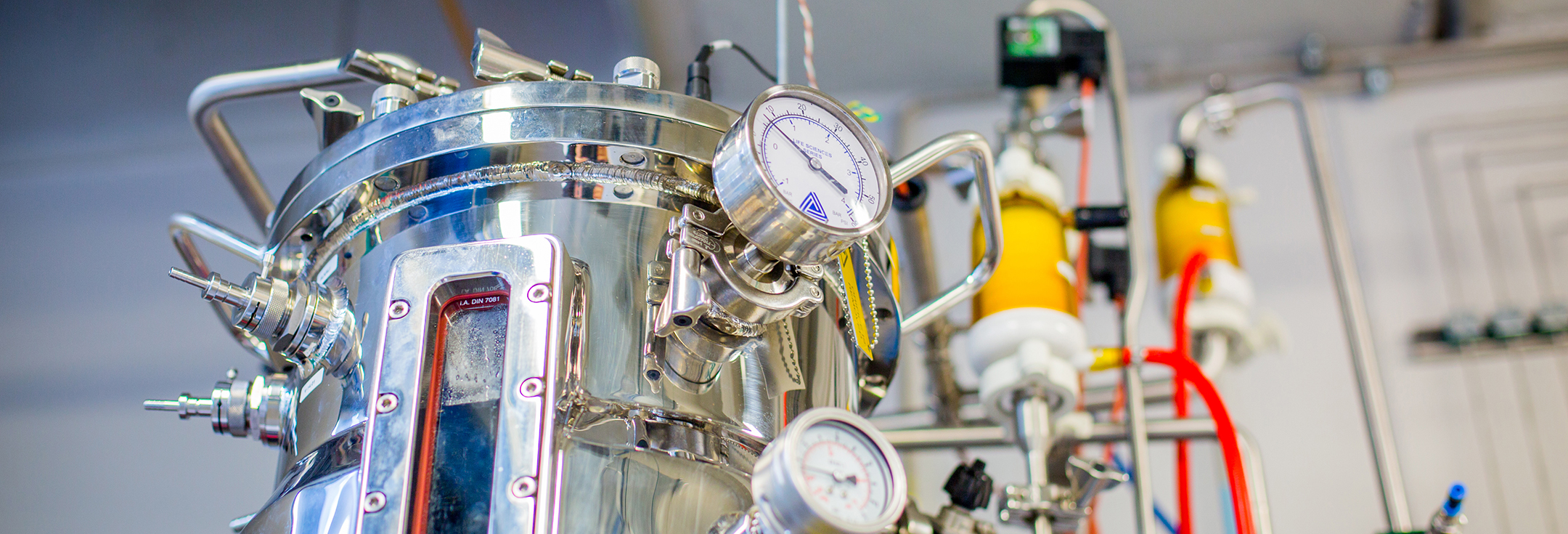

A variety of reactors are available within the department for testing biological reactions (fermenter, air-lift reactor), heterogeneously catalyzed reactions (fixed bed reactors, slurry reactors, Berty reactor), catalyst for fuel cells (fuel cell stations), crystallization processes (Eutectic Freeze Crystallizers and LabMax crystallizers) and precipitation reactions (multiphase stirred tank reactors, fluidised bed crystallizers and large scale (100L) multiphase reactors).

Mechanical Workshop

The Mechanical Workshop is a well equipped fabrication workshop, with the capacity for prototype development and customised designs in various materials, including stainless steel and Perspex.