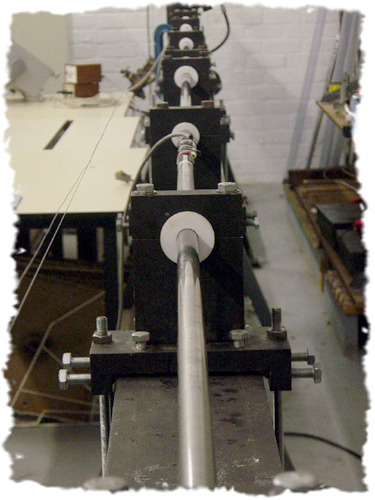

The Hopkinson bar is employed by BISRU in varying configurations, the most well known being the Split Hopkinson Pressure bar (SHPB) developed by Kolsky in 1948. The SHPB is used to determine the flow stress of materials at strain rates in the order of 103 /s. A small cylindrical specimen is rapidly compressed between co-axial Hopkinson bars. By causing a striker bar to impact on the end of the 1st (input) bar a stress wave is generated. This stress wave is partially reflected at the specimen interface and partially transmitted into the 2nd (output) bar. By analysing the three waves capture in the two bars the stress vs. strain behaviour of the specimen can be deduced.

Another useful configuration is the direct impact Hopkinson bar (DIHP). The DIHB is similar to the SHPB except that the input bar is removed and the striker bar is allowed to impact the specimen directly. The stress signal from the output is used to calculate the deceleration of the striker bar and hence the stress vs. strain behaviour of the specimen. Hopkinson bars are also used in conjunction with the Taylor test and the instrumented ballistic pendulum.