Academia and industry working together to develop solutions for reusable masks

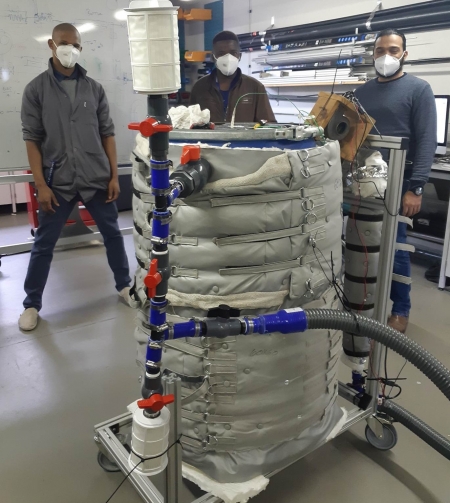

Pictured are Darryn Stevens, Aviwe Poswayo and Uthmaan Basardien (all of Cape Catalytix) with the V2 prototype. The other team members are Prof K Dheda (Pulmonology), A/Prof S Sivarasu (Biomedical Engineering), J le Roux (FHS), Prof M Claeys (CHE), Prof J Fletcher (CHE) and S Roberts (Cape Catalytix)

PPE is critical to COVID-19 management and treatment. However, in sub-Saharan Africa, availability of appropriate PPE and the significant cost of single-use items is a major challenge.

To help address this issue, researchers from the UCT Chemical Engineering Department, UCT Faculty of Health Sciences as well as Cape Catalytix (Pty) Ltd are working together to develop an N95 mask decontamination device which will allow re-use of the N95 masks.

The self-contained system will use vapourised hydrogen peroxide for the decontamination process and will be made from readily and inexpensively available components. The first design will have a ~100L working volume and be able to treat 40-50 masks per cycle. It is aimed at South African medical facilities dealing with COVID-19 infections. Larger installations for e.g. emergency COVID-19 field hospitals are envisaged to follow.